Yup do that too, from the threaded end so dirt isn't attracted to it, not sure it matters. I also follow Specialized's advice to put some grease on the thread.Yep I do the same and also lube the o ring with liquid silicone. It is also worth pushing some grease into the hollow battery fixing brass screw. It prevents dust and grit migrating via the hole to the threads.

I would think an airtight seal like clingfilm could cause sweating. Something like neoprene would be better.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Common rider inflicted motor failures

- Thread starter Al Boneta

- Start date

Supratad

Well-known member

The long bolt that secures the plastic flap to the battery, or the big short bolt?It's under the bolt head and usually comes off with the bolt. It's such a good colour and size match I didn't know it was there until it slid part way down the bolt.

The long one.The long bolt that secures the plastic flap to the battery, or the big short bolt?

Supratad

Well-known member

Ah good, I saw that and saved the little washer.

Supratad

Well-known member

OK ta, all duly noted and I have some silicone grease already.

Rusty

E*POWAH BOSS

Having a re-read of this thread and noting all the various arguments about max power etc, I think what everyone is missing is the crucial element .... LOAD.

Running an electric motor at full power and/or high revolutions really is not too big an issue as long as there is acceptable cooling. However, run that motor in the same situation under high load and it will overhead and fail fairly quickly.

I had the opportunity to look at a few drive belts from failed Brose motors last night (out of warranty ones) and what was apparent was that they appeared to be effected by heat. That leads me to believe that the Brose motor creates sufficient heat that it can weaken a belt. The guy working on them surmises that those he has worked on should last a great deal longer than originally as he has used different manufactured belts that theoretically should hold up under higher temperatures. As of not, he has not had any return and the first ones he did were about 18 months ago.

Could be that Brose are using a low-mid priced belt and by putting in a top of the line one might improve reliability? Chris said the belts he used were almost treble the price of the cheap Chinese belts available, but I doubt a German manufacturer would be using a budget Chinese belt.

Anyways, back to my initial point LOAD.

Running a temperature sensor it would be interesting to see the difference between doing say 15kph spinning in a low gear with a high cadence for say 20 minutes as opposed to lugging at the same speed in a high gear.

Running an electric motor at full power and/or high revolutions really is not too big an issue as long as there is acceptable cooling. However, run that motor in the same situation under high load and it will overhead and fail fairly quickly.

I had the opportunity to look at a few drive belts from failed Brose motors last night (out of warranty ones) and what was apparent was that they appeared to be effected by heat. That leads me to believe that the Brose motor creates sufficient heat that it can weaken a belt. The guy working on them surmises that those he has worked on should last a great deal longer than originally as he has used different manufactured belts that theoretically should hold up under higher temperatures. As of not, he has not had any return and the first ones he did were about 18 months ago.

Could be that Brose are using a low-mid priced belt and by putting in a top of the line one might improve reliability? Chris said the belts he used were almost treble the price of the cheap Chinese belts available, but I doubt a German manufacturer would be using a budget Chinese belt.

Anyways, back to my initial point LOAD.

Running a temperature sensor it would be interesting to see the difference between doing say 15kph spinning in a low gear with a high cadence for say 20 minutes as opposed to lugging at the same speed in a high gear.

.....and that is what I was describing in term of riding experience earlier in the thread. Typically electric motors are most efficient at 75% of their max rated load....and designed to operate at loads c 30% in excess of their max rating only for short periods of time. It is not only the belt that may suffer the consequences of sustained high loads over its rated max. Greases may break down and bearing materials expand leading to increased friction. My earlier post refers to the increase in noise I could hear as load increased and how using both gears and modes could keep the motor running near silent. Maybe the belt is designed to be the weakest link to protect other components like the planetary gears.

Having a re-read of this thread and noting all the various arguments about max power etc, I think what everyone is missing is the crucial element .... LOAD.

Running an electric motor at full power and/or high revolutions really is not too big an issue as long as there is acceptable cooling. However, run that motor in the same situation under high load and it will overhead and fail fairly quickly.

I had the opportunity to look at a few drive belts from failed Brose motors last night (out of warranty ones) and what was apparent was that they appeared to be effected by heat. That leads me to believe that the Brose motor creates sufficient heat that it can weaken a belt. The guy working on them surmises that those he has worked on should last a great deal longer than originally as he has used different manufactured belts that theoretically should hold up under higher temperatures. As of not, he has not had any return and the first ones he did were about 18 months ago.

Could be that Brose are using a low-mid priced belt and by putting in a top of the line one might improve reliability? Chris said the belts he used were almost treble the price of the cheap Chinese belts available, but I doubt a German manufacturer would be using a budget Chinese belt.

Anyways, back to my initial point LOAD.

Running a temperature sensor it would be interesting to see the difference between doing say 15kph spinning in a low gear with a high cadence for say 20 minutes as opposed to lugging at the same speed in a high gear.

Agree with you on the excessive heat causing belt failures. BLEvo tracks motor temperature and also battery temperature so this information can be available ‘live’ as you ride if you so wish.

Can we also clear something up regarding BLevo.

Using BLEvo has absolutely no adverse affect on your motor or warranty ‘IF’ you ‘DO NOT‘ use the ‘derestriction’ facility.

Before Blevo was around people used a Bluetooth App called LightBlue to derestrict their 2016, 2017, 2018 Levo’s and the 2018, 2019 Kenevo’s and some of the early 2019 Levo’s. It was a very task to carry out and there were various HEX codes you could input to change you wheel size from 2000mm down to 800mm.

My recent personal experience points more towards heat killing motor belts rather than speed exceeding 30mph. I may be wrong but the following examples are 2 different experiences.

1. Out on a ride with my friend who has a one year old 2019 Levo that is derestricted to 36kph as for him, that is the ‘sweet spot’ that he needs set to prevent the motor cutting out on him when he is riding ‘UP’ flowing single track trails.

His belt failed on an very cold early morning ride a few weeks back when I was out with him smashing out our regular steep climbing and descending session that we like to do to get the old tickers pumping and keeping the mileage turning over. In that session we were both on Turbo set at 100/100 with Shuttle ’ON’. We only averaged 15kph on the climbs as a lot of the climb is between 15 to 22% (so please note, he had no advantage with his derestriction on the climbs). We never exceeded 50kph on the descents as we free wheeled about 90% of it due to how steep the descent was plus it was dark and we were on a very narrow public single track road and could not see around some of the corners and did not really want to be involved in an early morning head on with a car. 1090 metres climbed and descended in under 55 minutes so as you can see by the time we were riding both bikes at a reasonably quick pace. Just over the hour mark and on the way up again for the last time there was a sound like a stuck pig squealing and we both knew it was his belt that had failed. I checked my BLEvo stats after the ride and my motor had registered a maximum temp of 69 degrees on this ride, his max reading was 67 degrees so slightly lower than mine.

2. Out on a ride with my other friend who had a belt failure and had a stock 2018 Levo with NO derestriction enabled. We we’re climbing up a very long, steep climb in July when his belt failed and started squealing like a stuck pig. I did not have BLEvo on so did not capture the Maximum motor temperature stats at the time but the engine covers were fairly hot to touch so at a guess it was probably the same or close to the above (around the 60 degree plus mark). We were both on Turbo set at 100/100. I had my 2019 set with Shuttle ’ON’.

Last edited:

GrandesRoues

Member

You've lost me here.

The motor is not putting out more power. That is an impossibility.

Power on ebike is software limited, to comply with the 250W regulation.

For this demonstration, i will consider long term continuous use at 250W, as in the regulations.

(the regulation allows for short periods of time, to exeed 250W. I have seen numbers around 750W !)

An electrical motor have a nearly flat torque cuve (traced against velocity). Thus as power is torque * rotational velocity, the software HAVE to limit the torque to not go over 250W.

To do this, it essentially limits the amps feed to the motor, with a law where amps decrease with velocity. This software law is implemented in the controller by the manufacturer.

If the sensor information on speed is falsified, then the software believes the motor is still not outputting 250W and feeds the motor with more amps than it should. This gives more mechanical power. The bike is faster !

Of course power is not free, and so this hack will also consumme more power, ie more amps, and the barrery is drained faster.

In the motor, heat produced is linked to the amps squared, so this setup using on average higher amps, can lead to overheating if the system is not able to cope with it.

Last edited:

GrahamPaul

E*POWAH Elite World Champion

Power on ebike is software limited, to comply with the 250W regulation.

For this demonstration, i will consider long term continuous use at 250W, as in the regulations.

(the regulation allows for short periods of time, to exeed 250W. I have seen numbers around 750W !)

An electrical motor have a nearly flat torque cuve (traced against velocity). Thus as power is torque * rotational velocity, the software HAVE to limit the torque to not go over 250W.

To do this, it essentially limits the amps feed to the motor, with a law where amps decrease with velocity. This software law is implemented in the controller by the manufacturer.

If the sensor information on speed is falsified, then the software believes the motor is still not outputting 250W and feeds the motor with more amps than it should. This gives more mechanical power. The bike is faster !

Of course power is not free, and so this hack will also consumme more power, ie more amps, and the barrery is drained faster.

In the motor, heat produced is linked to the amps squared, so this setup using on average higher amps, can lead to overheating if the system is not able to cope with it.

Ah. I think we might be getting somewhere. A case of meanings getting lost in translation.

I agree, the motor torque curve is (mostly) horizontal with respect to motor rotational (angular) velocity.

I agree, the motor output of 250W is based on an average value which can be exceeded over the short term.

The motor input of 250W is thus an average value controlled by the amps fed to the motor. Amps can be increased for a short period as long as the 250W output, averaged over time, is maintained.

I agree, the bicycle speed as well as the motor rotational velocity is fed back into the motor software along with pedal cadence.

It is the combination of pedal cadence, bicycle speed and motor speed (angular velocity) from which the motor software will determine the actual amperage supplied to the motor - which can exceed 250W in the short term.

By fiddling with the bicycle speed input, a higher amperage can be fed to the motor for more time than the motor was designed for.

As you say, heat generation is proportional to the square of the amps.

Does that summarise your proposals?

Last edited:

Again, BLEvo outputs all of this info to allow you geeky guys to absorb.

Maximum Amp draw from the battery is just above 20Amps on most 2018, 2019 and 2020 Levo’s and as @GrandesRoues says in his post above, I to have seen 750 Watts of power output in short bursts.

There is a csv file that BLEvo creates on every ride that has this detail and of course loads of other info. I think from memory its data output capture is carried out every second.

Maximum Amp draw from the battery is just above 20Amps on most 2018, 2019 and 2020 Levo’s and as @GrandesRoues says in his post above, I to have seen 750 Watts of power output in short bursts.

There is a csv file that BLEvo creates on every ride that has this detail and of course loads of other info. I think from memory its data output capture is carried out every second.

Last edited:

GrandesRoues

Member

@GrahamPaul : yes

@Kiwi in Wales this csv file is interesting, and it would be even better to have at the same time the mechanical power at the whell with a powertap hub.

@Kiwi in Wales this csv file is interesting, and it would be even better to have at the same time the mechanical power at the whell with a powertap hub.

wrayb

Member

If the sensor information on speed is falsified, then the software believes the motor is still not outputting 250W and feeds the motor with more amps than it should. This gives more mechanical power. The bike is faster !

OK...now this may be what I need to see...so I was under the impression the magnet/pickup to determine the RPM of the rear wheel (the speed of the bike) was there to be a simply switch to turn off the motor at a specific speed (20 mph in the US)...what you are indicating is the RPM of the rear wheel is an input used by the software to determine how many amps to draw from the battery??? Is that true?

Last edited:

I think speed certainly plays a bigger role in the software algorithm than acting as a cut off. I am interested how the planetary gearing works in practise. If speed is low and the bike is being driven uphill without yet having gained any momentum. Crank torque could be high but cadence low. In turbo the motor is trying to achieve max output but cannot drive the crank any faster than the rider is pedalling. The motor must be spinning fast and the planetary gears acting as a slipping clutch? Anyone know how this works.

wrayb

Member

I think speed certainly plays a bigger role in the software algorithm than acting as a cut off.

Can someone confirm and elaborate on how the speed of the bike (rpm of the rear wheel) plays a role in the software, specifically how does this effect the output (horsepower) of the motor (or should I say the amp draw from the battery)?

beutelfuchs

Active member

Well, that´s nice theory. I would think what counts in practice is what a typical bikeshop mechanic can see on his diagnose tool and if that information is even fine grained enough to differ between "there was some app connected via BT" and "the speed limit was increased beyond default".Using BLEvo has absolutely no adverse affect on your motor or warranty ‘IF’ you ‘DO NOT‘ use the ‘derestriction’ facility.

Because thats probably what the Spec claim department will ask the mechanic to base his judgement on.

So again my question: Does anyone know out of experience how exactly tampering is diagnosed and more specifically, if Blevo usage without speed increase can even be detected or not?

Well, that´s nice theory. I would think what counts in practice is what a typical bikeshop mechanic can see on his diagnose tool and if that information is even fine grained enough to differ between "there was some app connected via BT" and "the speed limit was increased beyond default".

Because thats probably what the Spec claim department will ask the mechanic to base his judgement on.

So again my question: Does anyone know out of experience how exactly tampering is diagnosed and more specifically, if Blevo usage without speed increase can even be detected or not?

I think @Kiwi in Wales summed it up quite simply for you ??

Specialized don't have a problem with you using blevo, egenesis or anything else. It's an open system. You can use those apps with your bike to read information. You can also use them to change the settings which you can already change with mission control. Blevo gives you more information, so some people prefer to use blevo instead of mission control. Well done specialized for not locking us all down to one piece of software.

For the older bikes, you can also use blevo to change the wheel size - and therefore, influence the limited speed of the bike. Originally, you could do this with Mission Control. This option was removed from MC and later, they removed the facility for Blevo/eGenesis to change this information on the newer bikes.

If you want you can just use a bluetooth editor to change the support levels, if you don't want to use mission control, blevo or whatever and just like calculating hex numbers - for me , that's the highlight of a ride .. "ah yes, FFEF next time for more fun ...."

None of them enter a variable field and say "adjusted by Frank using Blevo".

The TCU's do have some historical memory function. So they can see some of your previous settings as well as the settings you have now. So if you've changed your wheel size, there's a reasonable chance they can see that data depending on when and how you did it.

The TCU also has a tiny pin hole camera which records the riders face and the last 2 hours of any sounds - so make sure you don't say anything bad about your bike mechanic. It also contains a humidity sensor to check for aquatic abuse, unfortunately, they had to leave the TCU unsealed for the sensor to work properly. Using a fuzzy logic algorithm, rider weight is also calculated by using the motor torque sensor to register suspension movements compared to bike speed when you're not pedalling. The idea is to check for increased rider weight and be able to reduce assistance accordingly. Most people will notice a 10% range increase after Christmas. It's all clever stuff ..

OK, so the last paragraph is made up...

beutelfuchs

Active member

Thanks, I know the background and I can actually read what others have written and I also have sufficient fantasy to speculate.

But I want to ask how its handled in practice, i.e. what the standard bike shop diagnosis tool can actually read out and what not.

If you don´t know, because maybe you are not working in a bike shop, don't bother.

But I want to ask how its handled in practice, i.e. what the standard bike shop diagnosis tool can actually read out and what not.

If you don´t know, because maybe you are not working in a bike shop, don't bother.

Please accept my apologies for wasting your time.Thanks, I know the background and I can actually read what others have written and I also have sufficient fantasy to speculate.

But I want to ask how its handled in practice, i.e. what the standard bike shop diagnosis tool can actually read out and what not.

If you don´t know, because maybe you are not working in a bike shop, don't bother.

If we can be of any possible help with any other problems, despite our inferiority, don't hesitate to ask.

You could ask @Al Boneta @Swan or @Bryan Wells , but as I'm sure as an intelligent men you'd understand that they wouldn't be able to give that information out.

So I'm afraid you're just stuck with the Muppets or its a case of Fuchs off.

Last edited:

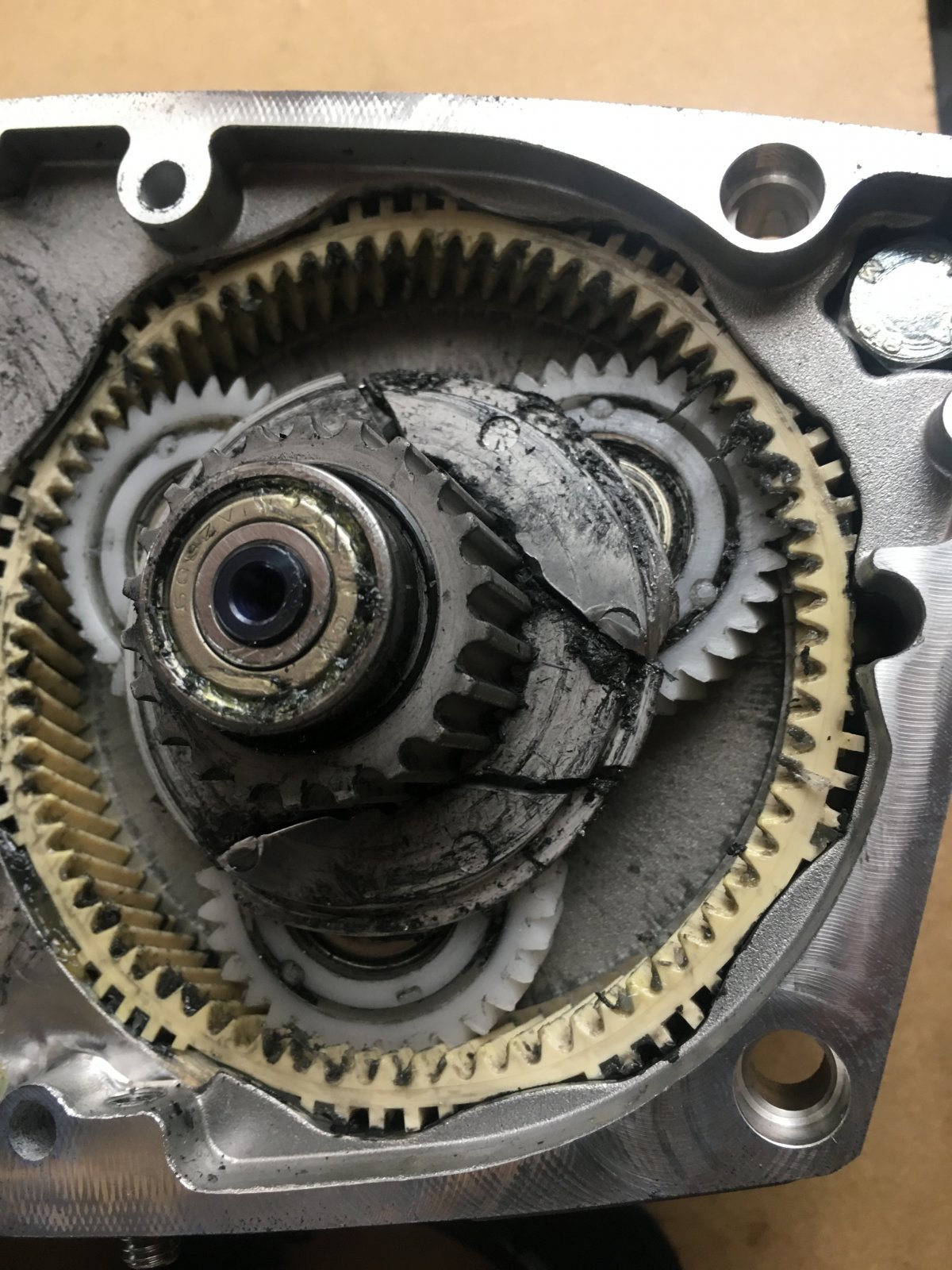

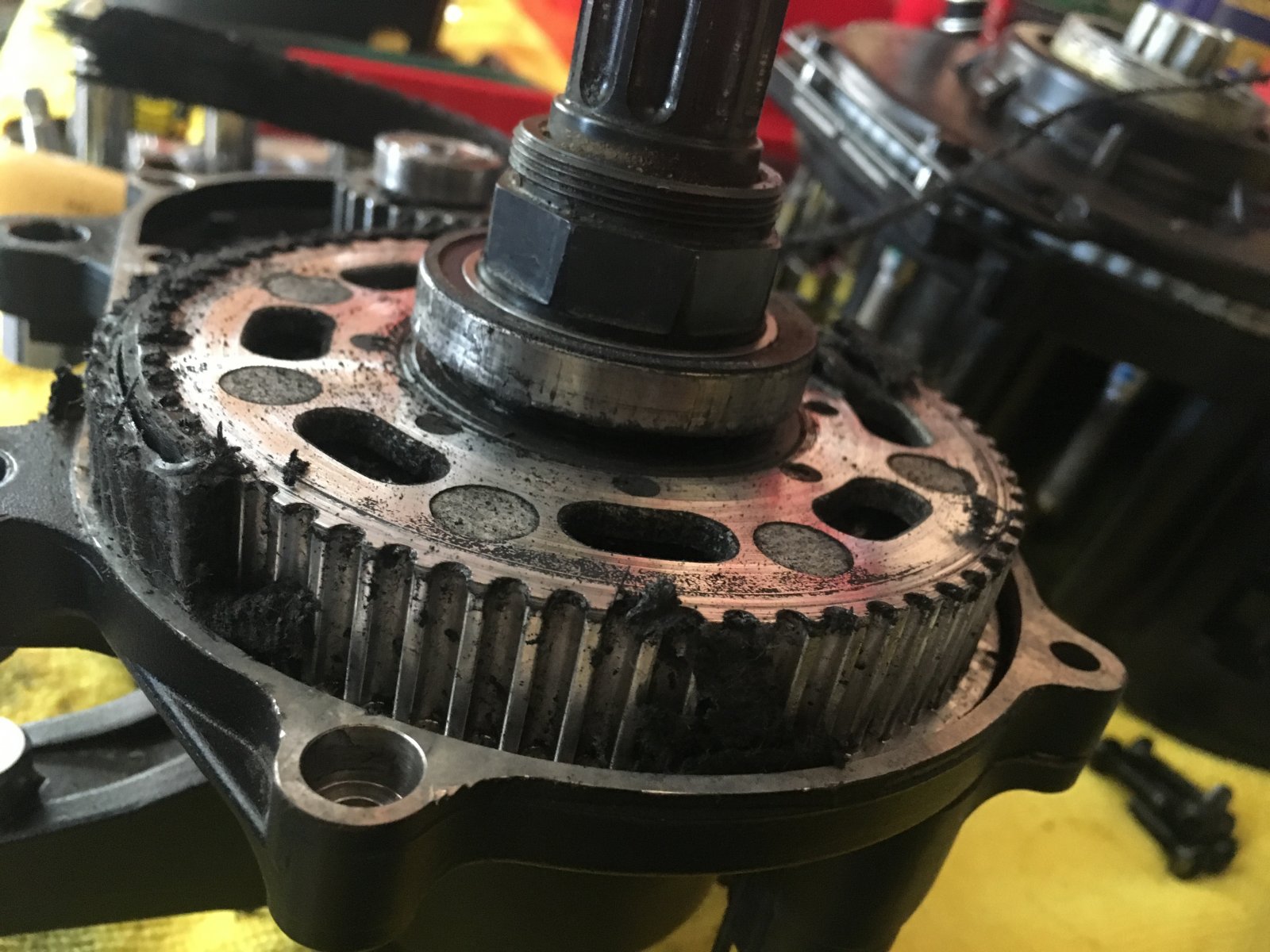

Just to throw another spanner in the works, I too have seen my fair share of shredded belts, snapped belt tensioners, shattered ceramic belt pulleys and snapped planet gear drive shafts. These were all before the invention of BLEvo.

After speaking with a few customers it seems there is also another reason for this phenomena, the simple peddle strike!

When the motor is spinning, there is great inertia and energy going on inside. If you strike the pedal and stop the motor dead (even momentarily) all that energy and inertia must go somewhere and it normally ends up snapping or stripping the belt or destroying the pulleys, snapping the tensioner etc.

Just to clear something else up. Brose have a carbon infused belt manufactured for them by Gates UK. All other cheaper belts currently on the market generally use fibreglass strands and from our experience are definitely inferior.

There are other reasons for a belt to overheat, if the tensioner is too tight for example. Or if the belt has been fitted dry.

However, I must agree that putting extra power through a belt drive is always a pretty bad idea.

After speaking with a few customers it seems there is also another reason for this phenomena, the simple peddle strike!

When the motor is spinning, there is great inertia and energy going on inside. If you strike the pedal and stop the motor dead (even momentarily) all that energy and inertia must go somewhere and it normally ends up snapping or stripping the belt or destroying the pulleys, snapping the tensioner etc.

Just to clear something else up. Brose have a carbon infused belt manufactured for them by Gates UK. All other cheaper belts currently on the market generally use fibreglass strands and from our experience are definitely inferior.

There are other reasons for a belt to overheat, if the tensioner is too tight for example. Or if the belt has been fitted dry.

However, I must agree that putting extra power through a belt drive is always a pretty bad idea.

wrayb

Member

However, I must agree that putting extra power through a belt drive is always a pretty bad idea.

However, I must agree that putting extra power through a belt drive is always a pretty bad idea.

What "extra power" are you referring to? From de-restricting? I am trying to understand how de-restricting would result in any extra power through the belt drive. Can you help me with this?

@Bearing Man thanks for your input - whilst I understand you dont want to say one motor is better than the other, and from my point of view they all have god points and bad, but would you be able to say in your opinion which one is the best put together?

Extra power is not added by de-restricting as implied by the name and most dongles do just that (put the motor back to what it was originally designed to do) But if a "tuning chip or app were applied and this could maintain in excess of 250W for extended periods of time, then you are asking for trouble.What "extra power" are you referring to? From de-restricting? I am trying to understand how de-restricting would result in any extra power through the belt drive. Can you help me with this?

I can't speak for the BLEvo app because I have yet to play with one to see exactly what it does and how it does it?

Yes! I am bursting to say this, but I can't do this on a public forum, sorry.@Bearing Man thanks for your input - whilst I understand you dont want to say one motor is better than the other, and from my point of view they all have god points and bad, but would you be able to say in your opinion which one is the best put together?

Is it the Brochimaha ?Yes! I am bursting to say this, but I can't do this on a public forum, sorry.

Ohhh ... I missed panasonic ... no one seems to complain about their panasonic motors breaking .. but then if they didn't break, you wouldn't know if they were good or not .. what a dilemma ..

wrayb

Member

Extra power is not added by de-restricting as implied by the name and most dongles do just that (put the motor back to what it was originally designed to do) But if a "tuning chip or app were applied and this could maintain in excess of 250W for extended periods of time, then you are asking for trouble.

I can't speak for the BLEvo app because I have yet to play with one to see exactly what it does and how it does it?

Got it. De-restricting does NOT increase the mechanical power output of the electric motor. That seems to be a very misunderstood fact. I have always understood the rear wheel pickup for wheel RPM is simply a switch to turn off motor support when the RPM specified is reached (which would equate to 20 mph here in the US) and what you wrote backs that up (correct?).

Now I am curious about a "tuning chip" or "app" being applied to increase the mechanical output of the motor. Is there a thread on the forum describing either of these and how they work?

Thanks for the information.

Last edited:

Beekeeper

🍯Honey Monster🍯

Ohhh ... I missed panasonic ... no one seems to complain about their panasonic motors breaking .. but then if they didn't break, you wouldn't know if they were good or not .. what a dilemma ..

My microwave oven is a Panasonic and judging by the number of Pizza’s I eat, the motor on that has done way more miles than my bike. Nothing wrong with Panasonic motors ? ? ?

I think there are two types of derestricting.

I have never used BLEvo, but I did try one of the Shimano apps that allows you to do similar things, and tbh I wasn't a fan, as I found it was very easy to adjust the settings and end up with a power delivery that was a dogs dinner, and it made me realise that actually a lot of thought has gone into making the modes work well in the OEM format, especially in terms of reaction to cadence, rider input, and power delivery.

I concluded that you needed a pretty in-depth understanding of what adjusting all the parameters would do to both the motor and the power delivery if you where to (and I dont think this is possible, at least on the Shimano) come up with a better setting than the factory ones. I am not per say talking about altering the amount of assistance in each mode, as that is fairly straightforward, but how the power is delivered in each mode.

Now I am not saying anyone is an idiot for using these apps, as I also think that you can use an app like BLEvo in a simple way and not really muck around with the motor in a detrimental way, but I also think you can easily set the bike up in a way that is not going to be good for the motor.

- The first and most basic is altering the cutoff point of the assistance, either by a mechanical cheat device on the sensor such as the Badass Box, or by a dongle - this does not change how the motor delivers its power, or the preset modes for delivering said power within the bikes OEM software. The downsides/risk with this is that you will use more battery as you are getting more as assistance during a ride, and because the motor is always in use, very rarely you may find the motor gets up to a higher temperature and cuts out through being in constant use, though this is only likely to happen on a very hot day and if you are boosting around in turbo up hills non stop. The motor will also likely ware its components quicker vs a restricted bike, not due to stress, but due to more use per ride.

- The second way is by essentially hacking the bike with apps like BLEvo, where you can change how the bike delivers its power, and to an extent how much power is available. With these sort of apps you can change the parameters of the OEM software, and as such are moving away from what the manufacturer has deemed suitable for the motor. Obviously you run the risk here of putting far more stress on components in the motor if you are making the motor behave in a different way to what it was designed. You also have the same downsides as the mechanical cheat device in terms of battery use etc etc.

I have never used BLEvo, but I did try one of the Shimano apps that allows you to do similar things, and tbh I wasn't a fan, as I found it was very easy to adjust the settings and end up with a power delivery that was a dogs dinner, and it made me realise that actually a lot of thought has gone into making the modes work well in the OEM format, especially in terms of reaction to cadence, rider input, and power delivery.

I concluded that you needed a pretty in-depth understanding of what adjusting all the parameters would do to both the motor and the power delivery if you where to (and I dont think this is possible, at least on the Shimano) come up with a better setting than the factory ones. I am not per say talking about altering the amount of assistance in each mode, as that is fairly straightforward, but how the power is delivered in each mode.

Now I am not saying anyone is an idiot for using these apps, as I also think that you can use an app like BLEvo in a simple way and not really muck around with the motor in a detrimental way, but I also think you can easily set the bike up in a way that is not going to be good for the motor.

Sorry to disappoint the guy that wanted definitive info...something he is unlikely to get....and something even the lbs mechanic may not be able to answer... but from my experience of diagnostic tools built into devices that are processor driven it is relatively normal for the processor to maintain a log of the data inputs it receives. The question is then how that log is stored. It may for example have a limited storage capacity which is progressively overwritten as it fills meaning only a certain lapsed time amount of data is stored. That data ( if stored) would show the level of all inputs time based. So speed, amps drawn, voltage, torque, cadence. That data may be translated by the App used by the LBS or it may be just a spew of Hex code which only Spesh can interpret. If the TCU does not have that full capability now it almost certainly will have in future firmware updates. As already stated Spesh are happy for any app to modify settings etc so the use of any app that only does that is no problem. Any app that modifies wheel diameter etc will certainly be detectable in the near future, if not now, since the manufacturers are obliged to show they are taking all reasonable steps to ensure their pedelecs are operated in accordance with the regulations.

Similar threads

EMTB Forums

Since 2018

Join Our Community

The World's largest electric mountain bike community.

- 523K

- Messages

- 25,804

- Members

Latest articles

-

The lightweight Canyon Neuron:ONfly CF is here!

Finally, Canyon is out with their first mid-assist, lightweight emtb...- Knut Nes

- 6 min read

- Views: 529

- Reaction score: 2

- Comments: 1

-

New Sight VLT and Range VLT joins the 2024 Norco lineup

How many full-power emtbs have been launched this year? Yeah, Merida...- Knut Nes

- 2 min read

- Views: 4K

- Reaction score: 2

- Comments: 2