Just want to make everybody aware who has a Levo to check the shock bolt.

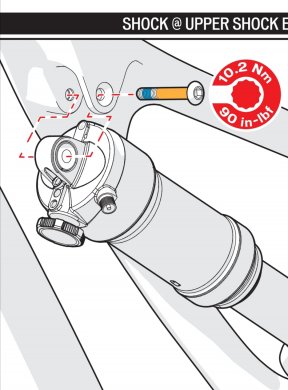

I have a 2020 Levo which has 1 year with a RockShox Deluxe, came with the bike. Today riding after a small drop I heard something break, did a quick check but could not see anything wrong and thought it might have been the mud guard until I got to the car to load the bike and could see that the shock bolt was loose got back home to tighten but the bolt did not tighten, manage to take off and to my surprise the bolt was snapped. The worst part is that the remaining piece of the bolt is in the threaded part of the frame,which for sure will not be easy to remove.

Looking at the problem now that has happened in my view this is a bad design of attaching the shock to the Levo frame,if the bolt snaps part is left in the frame potentially damaging the frame when extracted, basically almost the whole frame needs to be replace because of a bolt.

I guess that bolt should not snap, very dangerous if you were doing a jump or other.

I will contact the bike shop I bought for warranty repair.

I have a 2020 Levo which has 1 year with a RockShox Deluxe, came with the bike. Today riding after a small drop I heard something break, did a quick check but could not see anything wrong and thought it might have been the mud guard until I got to the car to load the bike and could see that the shock bolt was loose got back home to tighten but the bolt did not tighten, manage to take off and to my surprise the bolt was snapped. The worst part is that the remaining piece of the bolt is in the threaded part of the frame,which for sure will not be easy to remove.

Looking at the problem now that has happened in my view this is a bad design of attaching the shock to the Levo frame,if the bolt snaps part is left in the frame potentially damaging the frame when extracted, basically almost the whole frame needs to be replace because of a bolt.

I guess that bolt should not snap, very dangerous if you were doing a jump or other.

I will contact the bike shop I bought for warranty repair.