Tubby G

❤️🔥 Hot Stuff ❤️🔥

Now then. I’m trying to purchase a spoke wrench to tighten up my nipples (oo er).

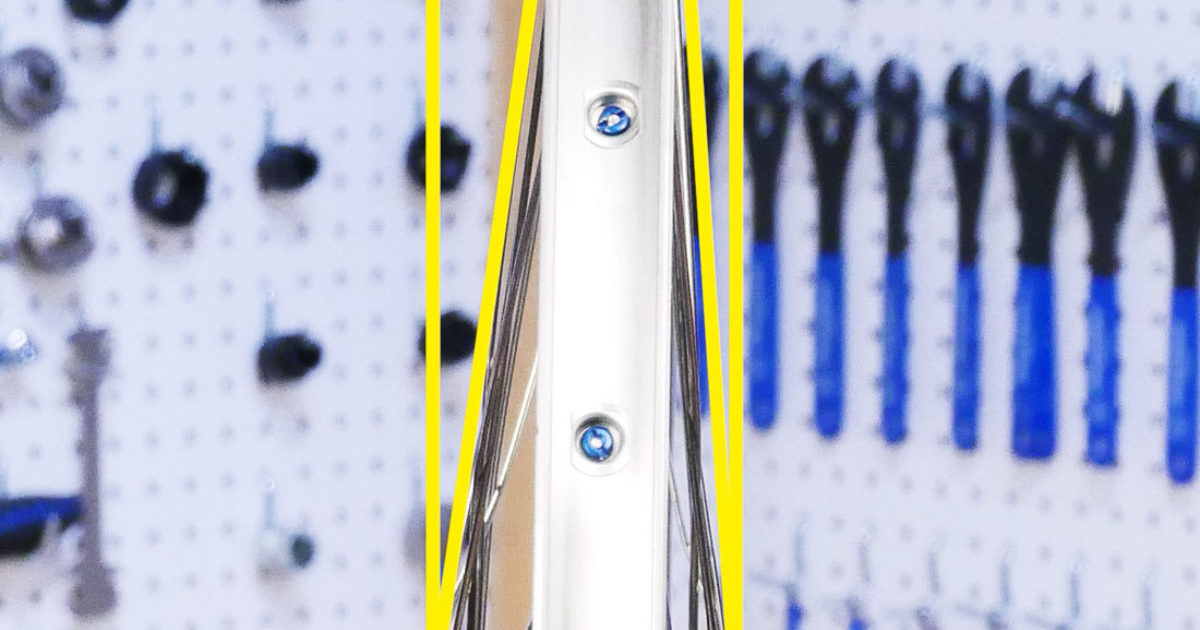

I contacted Orbea to ask what spokes they use on my Rise, and the spec sheet they sent me states Sapim Race J-Bend 4G (2mm) spokes with 2x14mm secure lock brass nipples

The Park Tool wrench I was going to buy is a 3 way multi tool, which covers the most common nipple sizes, 3.23, 3.3 & 3.45mm - Park Tool SW 7.2

I can’t find any spoke wrenches for 2mm nipples

Anyone an expert on nipples and know which tool I need to give them a good twist ?

I contacted Orbea to ask what spokes they use on my Rise, and the spec sheet they sent me states Sapim Race J-Bend 4G (2mm) spokes with 2x14mm secure lock brass nipples

The Park Tool wrench I was going to buy is a 3 way multi tool, which covers the most common nipple sizes, 3.23, 3.3 & 3.45mm - Park Tool SW 7.2

I can’t find any spoke wrenches for 2mm nipples

Anyone an expert on nipples and know which tool I need to give them a good twist ?

pretty sure my wheel build wasnt the cause

pretty sure my wheel build wasnt the cause