GrandPaBrogan

⚡ eGeezer ⚡

I don’t know about other EEBs but the Giant Trance e+Pro presents a dilemma when it comes to finding a spot to ‘hook’ a bike stand prong into. I’ve had several attempts in studying how to design a bike stand for it (that can also function as a work stand), but I’m left stumped each time. The only way I’ve been able to do this is to clamp a length of pipe against my workbench vice and hang the bike saddle over it. This is the only way I can rotate the drivetrain to check, repair or do service/maintenance to whatever (and also remove the rear wheel if needed). Problem is, I can’t use my workbench when the bike is hanging there and obviously I can’t store my bike like this. I could similarly fasten a pipe against a wall, but it'll be just as restrictive location-wise.

Below is what I came up with. Not saying this is the best way or the only way to do it, but for now - it works for me. The bike stand prong hooks underneath the top Maestro linkage. I inserted a rubber handlebar grip over the prong to act as a cushion and not scratch the paint.

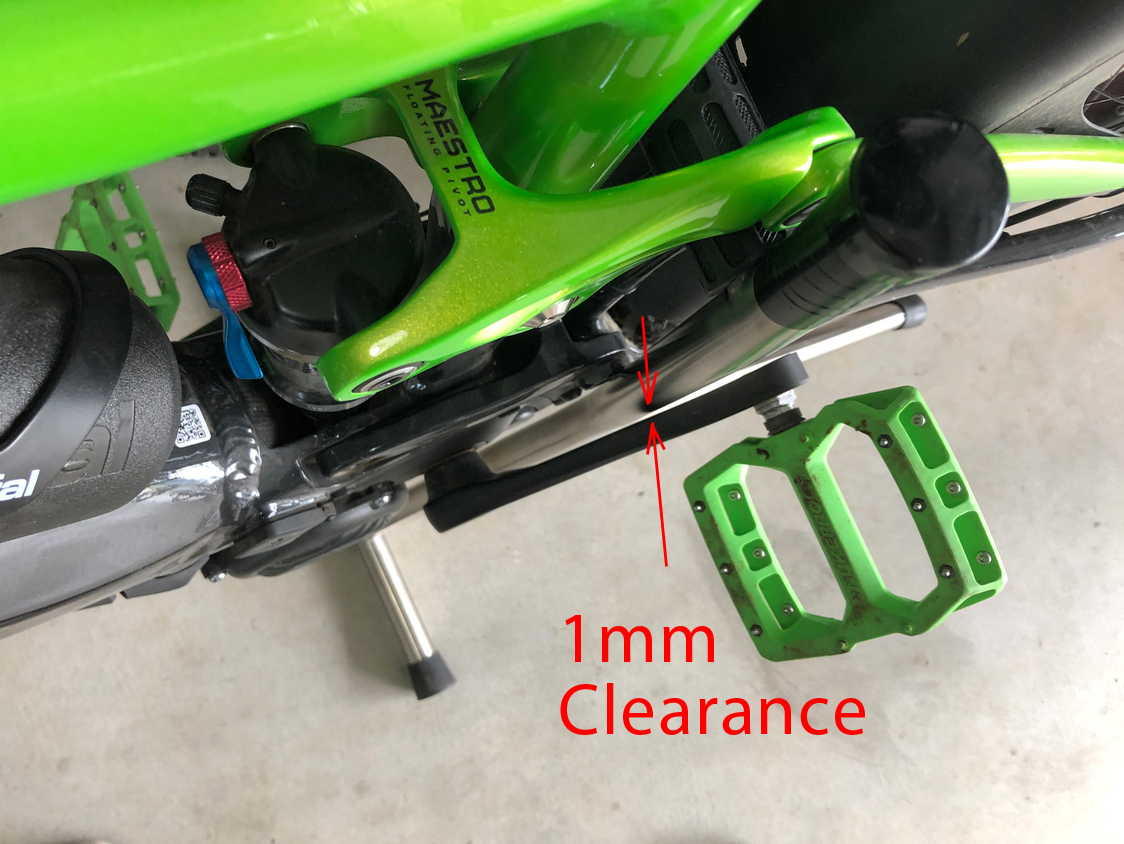

The tricky part is the clearance between the vertical member of the stand and the left crank arm (see below). The 1” diameter stainless steel tubing I used (25.4mm Ø) is only just clearing the arm by about a 1mm gap. It’s finicky… if the stand doesn’t hook-up precisely, or if the bike moves - the crank arm hits the stand. I might redesign it again later on, but next time will use a smaller 7/8” vertical tube (22.2mm Ø) but with a thicker wall thickness. The eBike is pretty heavy and a smaller diameter tube might flex if the walls aren't thicker.

Anyway, it works nicely as a park stand… and with a bit of care with positioning, I can get the cranks to rotate - which comes in handy when I want to apply chain lube before a ride - or quickly scrape the mushy crud off the derailleur jockey wheels (a pet hate of mine) with a popsicle stick.

.

Below is what I came up with. Not saying this is the best way or the only way to do it, but for now - it works for me. The bike stand prong hooks underneath the top Maestro linkage. I inserted a rubber handlebar grip over the prong to act as a cushion and not scratch the paint.

The tricky part is the clearance between the vertical member of the stand and the left crank arm (see below). The 1” diameter stainless steel tubing I used (25.4mm Ø) is only just clearing the arm by about a 1mm gap. It’s finicky… if the stand doesn’t hook-up precisely, or if the bike moves - the crank arm hits the stand. I might redesign it again later on, but next time will use a smaller 7/8” vertical tube (22.2mm Ø) but with a thicker wall thickness. The eBike is pretty heavy and a smaller diameter tube might flex if the walls aren't thicker.

Anyway, it works nicely as a park stand… and with a bit of care with positioning, I can get the cranks to rotate - which comes in handy when I want to apply chain lube before a ride - or quickly scrape the mushy crud off the derailleur jockey wheels (a pet hate of mine) with a popsicle stick.

.