Just started my annual strip down of my 2019 Levo Comp last done Jan 2020. Nearly 2 years now and zero faults.

First job was battery removal....it only gets removed once a year...bash guard off and a clean up.

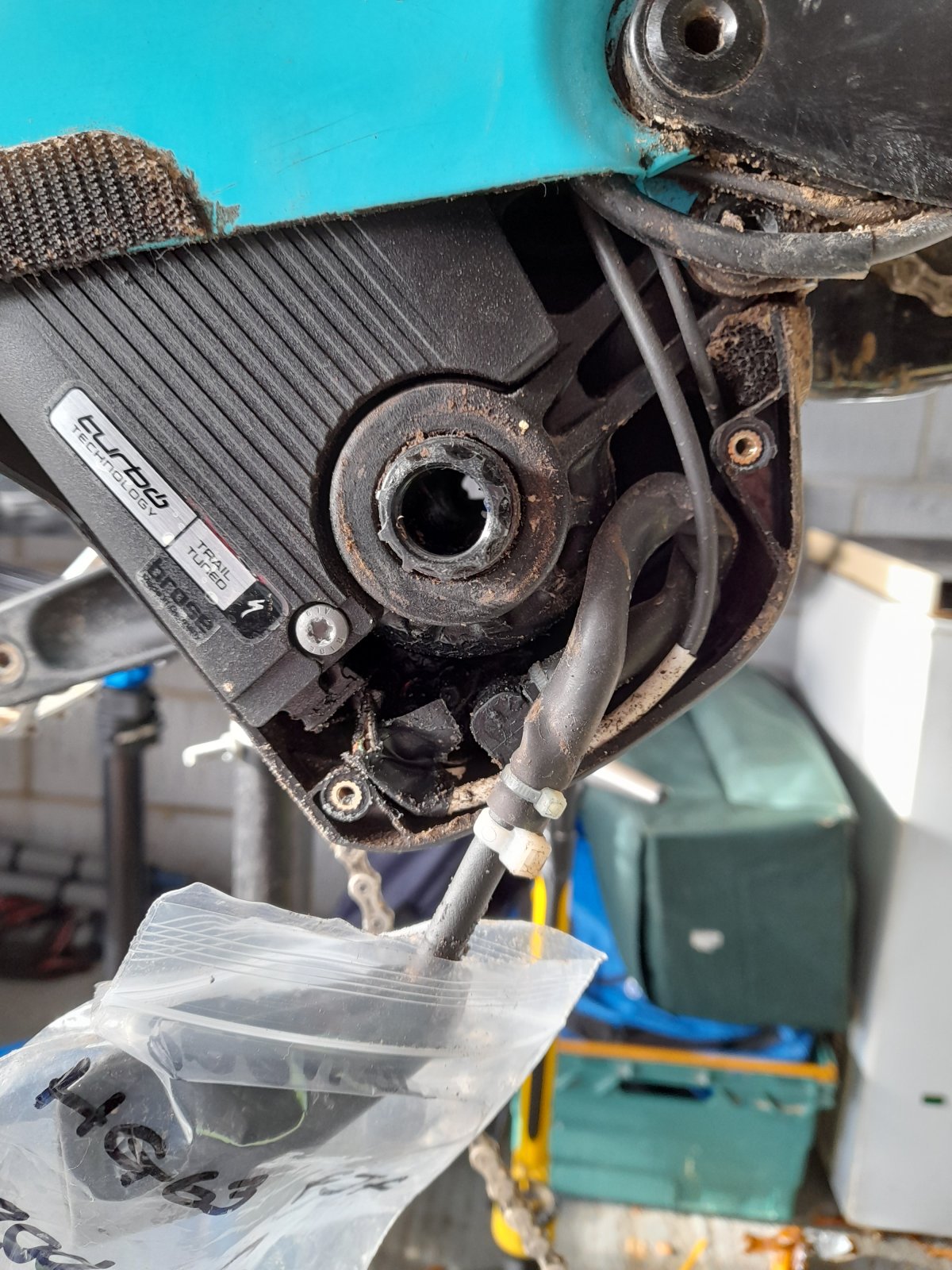

Second job was crank and motor cover off to clean out, clean all contacts and clean out the old grease and refresh it. All seals retreated with silicone lube.

There was minimal ingress of trail debris...just some dust on the grease. I renewed all the motofoam...the wedge inside, another strip pushed down the chain stay cross member and the hole where the speed sensor cable goes in.

I was probably one of the first to fit the new power cable last January. The good news is that mod seems to work as there is no damage to the cap and it is still fully sealed.

The motor cover has now been refined with a coating of grease on the upper edge and the bolts cleaned and locktite applied. The splined motor crankshaft fully cleaned and a small amount of grease applied, and the crank refused at 50nm.

First job was battery removal....it only gets removed once a year...bash guard off and a clean up.

Second job was crank and motor cover off to clean out, clean all contacts and clean out the old grease and refresh it. All seals retreated with silicone lube.

There was minimal ingress of trail debris...just some dust on the grease. I renewed all the motofoam...the wedge inside, another strip pushed down the chain stay cross member and the hole where the speed sensor cable goes in.

I was probably one of the first to fit the new power cable last January. The good news is that mod seems to work as there is no damage to the cap and it is still fully sealed.

The motor cover has now been refined with a coating of grease on the upper edge and the bolts cleaned and locktite applied. The splined motor crankshaft fully cleaned and a small amount of grease applied, and the crank refused at 50nm.