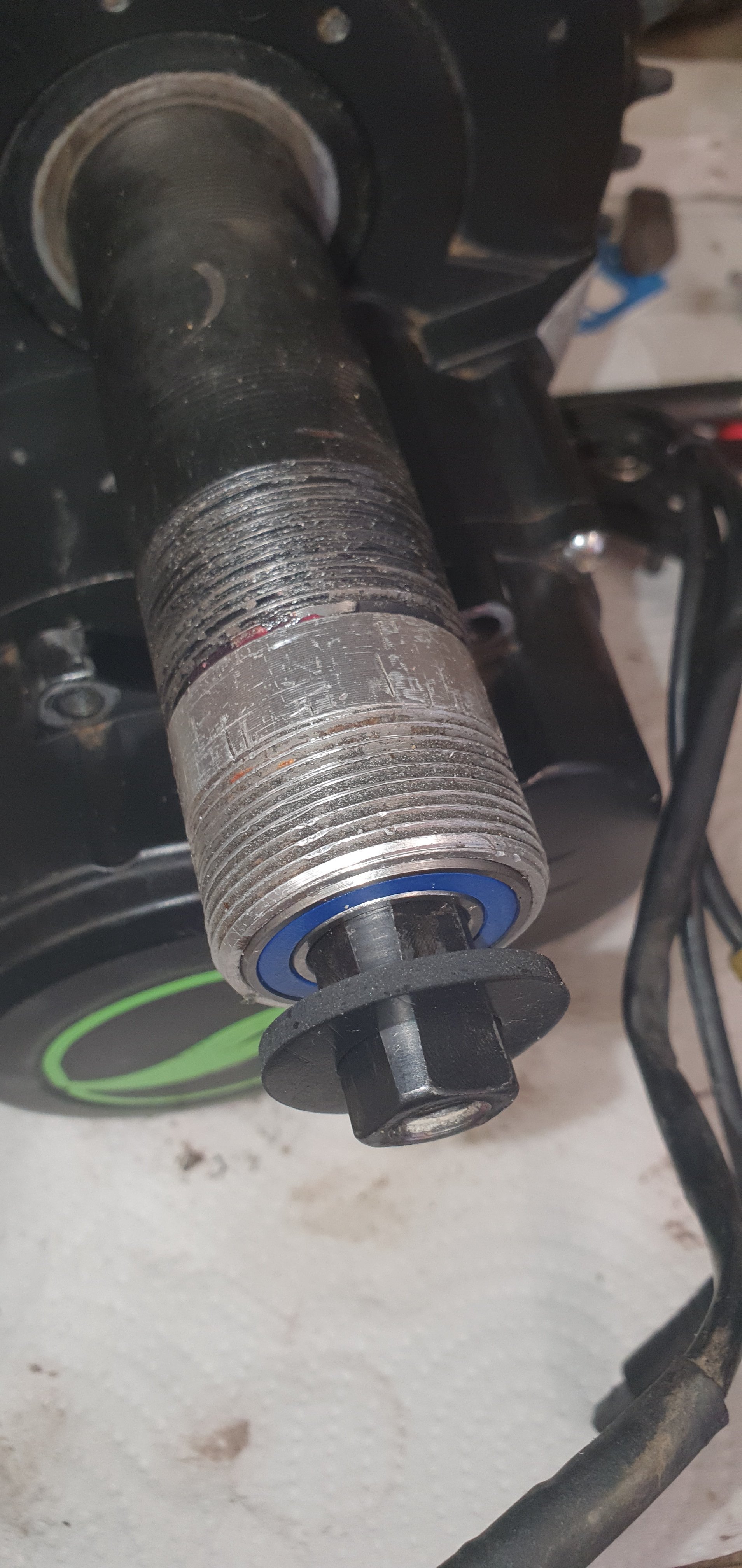

I have been riding a converted Giant Trance 4 with a Tongsheng TSDZ2 Torque sensing motor for nearly a year now. I am amazed how quiet the motor is (even compared to my mates Bosch) and many in my riding group have also commented the same. I upgraded the factory software with opensource software which has improved the start-up assistance from the torque sensor and continues to give PAS to 120 cadence. I am genuinely surprised these are not getting mentioned more. Very simple and easy to repair (if needed) and not hugely expensive. Breathes new life into your old MTB. Is any one else using one?

Last edited: