I propose to open this tread to share our .stl files for 3D printer.

We can mention in first:

Destination: exemple: "E10 frame"

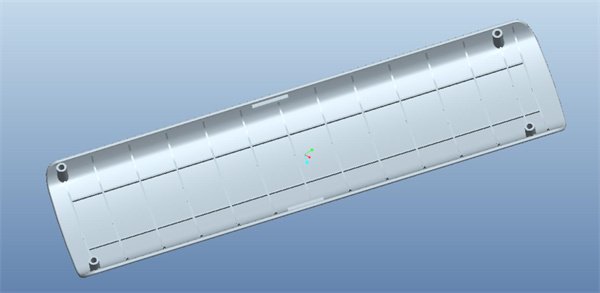

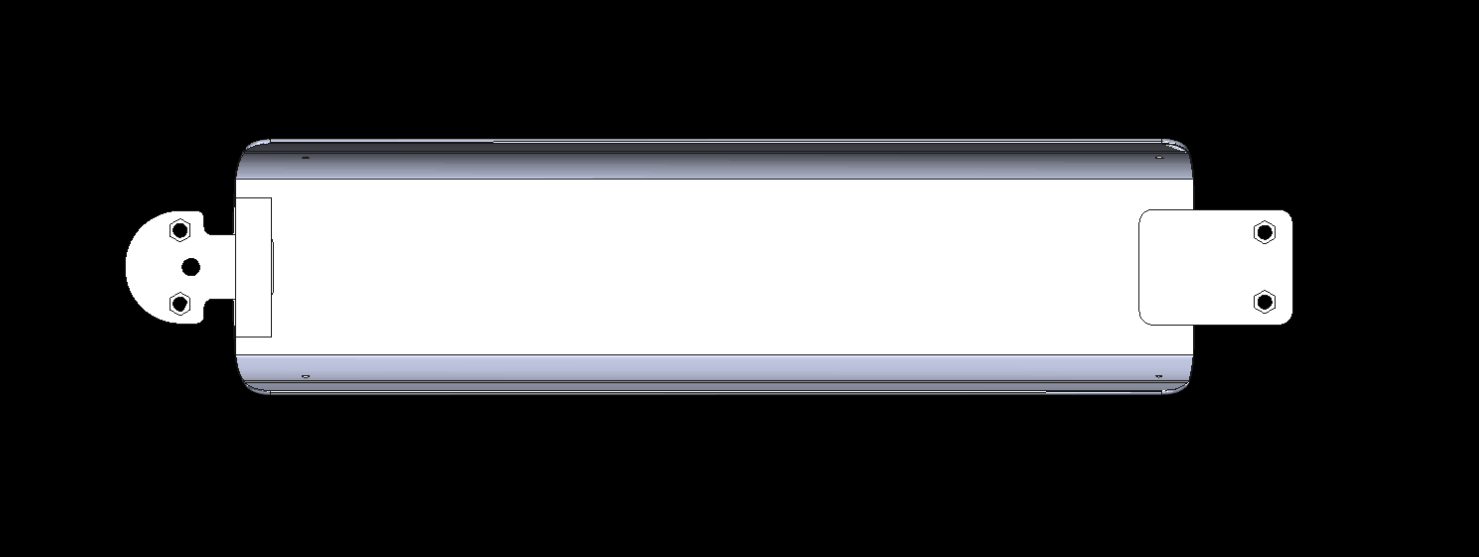

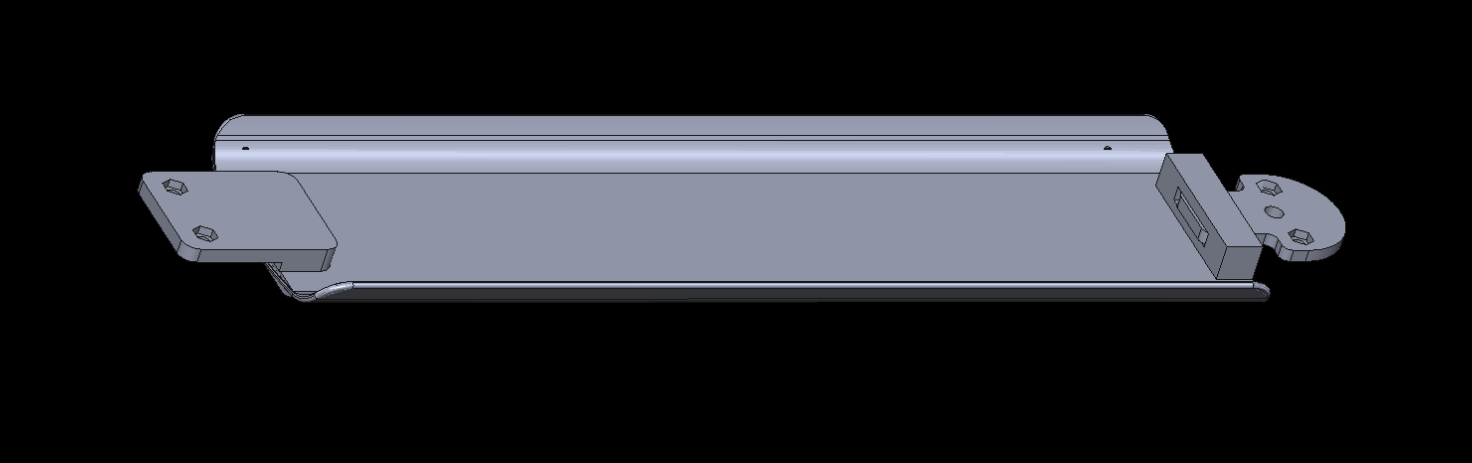

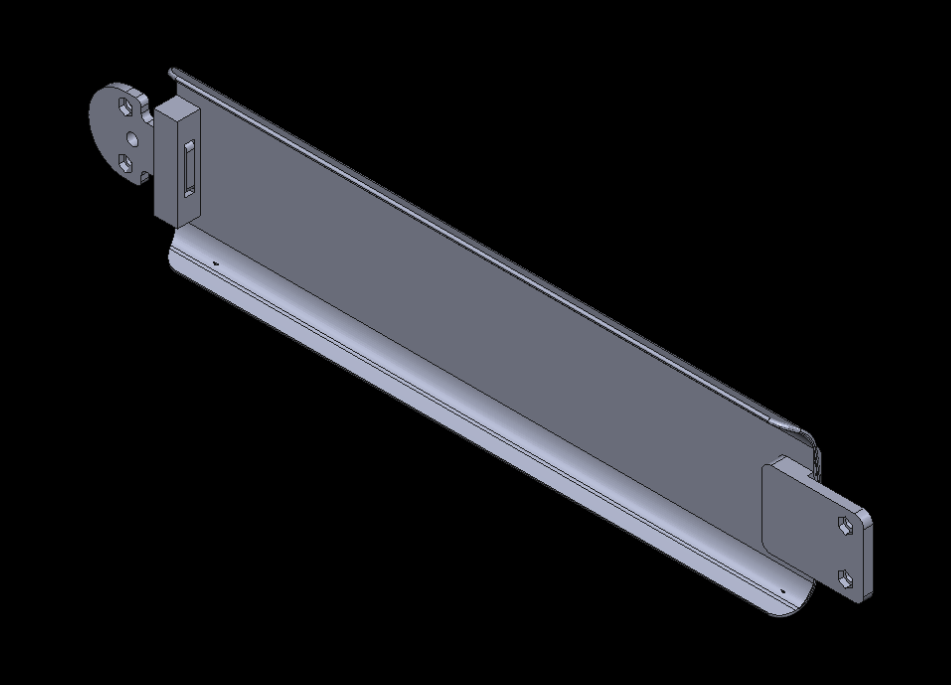

Function: exemple: "display DPC860C frame mount"

And we insert the file.stl (named.pdf to upload) + .jpeg if it is not perfect but functional (those can help somebody who want to build something near). Or thingiverse link for items finalized

My first deposit, based on initial build of "luky luke" to adapt display mounting at my frame:

We can mention in first:

Destination: exemple: "E10 frame"

Function: exemple: "display DPC860C frame mount"

And we insert the file.stl (named.pdf to upload) + .jpeg if it is not perfect but functional (those can help somebody who want to build something near). Or thingiverse link for items finalized

My first deposit, based on initial build of "luky luke" to adapt display mounting at my frame: