During a long ride and after switching from my first battery (External BT-E8010) which was at 10% to my second battery which was at 100%, this second battery throw an E020 error, which means:

E020:

So I checked the cables and removed and installed back the battery several times but it failed again inmediately. To finish the ride, I installed back the first battery which was at 10% and configured ECO to minimum assistance and after 25 additional Km mainly downhill with only 250m altitude gain Ï finished the ride with the battery at 7%

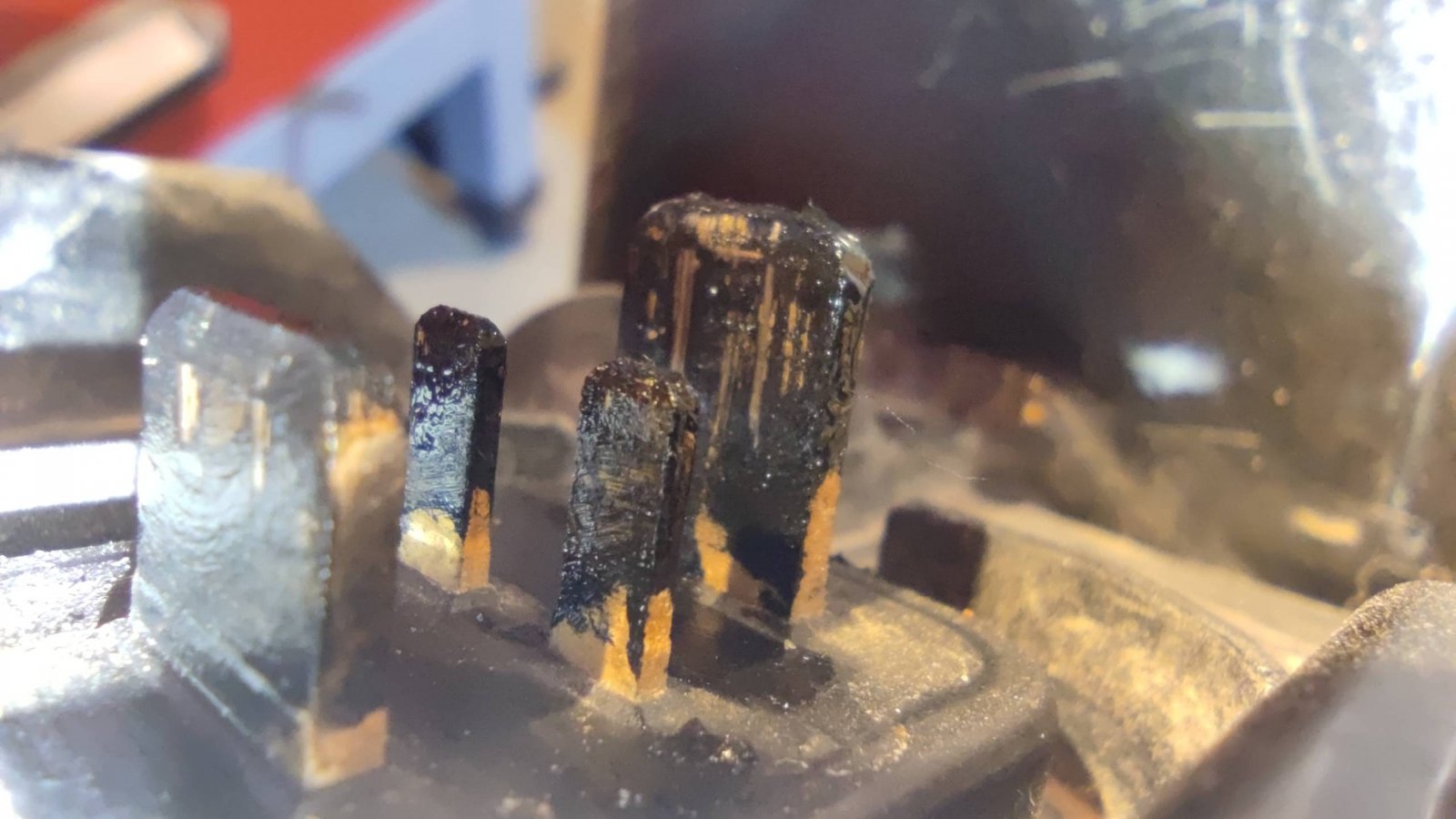

When at home I tried to fix the problem and I "painted" the male pins in the battery holderwith conductive grease and after plugging and unplugging the battery, the large male pins for positive and ground show that the battery socket (female) pins have pressed against them, but the small pins for communication do not show sign of contact with the battery socket.

So then I "closed" the spring tabs in the battery small center sockets (for communication with motor) so they make contact with the male pins in battery holder. As the hole is tiny I used a thin sewing pin to carefully press the "spring tabs" towards the center of the hole.

After this, battery started working again and there were no more error codes.

E020:

- A communication error between the battery and drive unit was detected.

- Power assistance is not provided during riding.

- Check that the cable between the drive unit and battery is properly connected.

So I checked the cables and removed and installed back the battery several times but it failed again inmediately. To finish the ride, I installed back the first battery which was at 10% and configured ECO to minimum assistance and after 25 additional Km mainly downhill with only 250m altitude gain Ï finished the ride with the battery at 7%

When at home I tried to fix the problem and I "painted" the male pins in the battery holderwith conductive grease and after plugging and unplugging the battery, the large male pins for positive and ground show that the battery socket (female) pins have pressed against them, but the small pins for communication do not show sign of contact with the battery socket.

So then I "closed" the spring tabs in the battery small center sockets (for communication with motor) so they make contact with the male pins in battery holder. As the hole is tiny I used a thin sewing pin to carefully press the "spring tabs" towards the center of the hole.

After this, battery started working again and there were no more error codes.

Last edited: