Tyjay

Member

As the motor just spins the crank doesn’t engage so that just spins aswellWhy don’t you hold the crank on the left side of the motor?

As the motor just spins the crank doesn’t engage so that just spins aswellWhy don’t you hold the crank on the left side of the motor?

That's half undone. If it's jammed at that point, then it's already f***ed. I'd either whack it hard with a punch, try to shock it loose or carefully dremel through it in one of the spindle valleys, throw it in the bin & get a new one. They're only aluminium.

Can't quite see from your pic but if your tool has a square/hex drive you should be able to hit with a rattle gun.Quick question been given a cube with the lock ring on but no chainring on

so when I turn it clockwise to loosen it, it obviously spins the motor as theres nothing to stop it from spinning

its an oldish bike probably gen 1/2 motor said I’d have a look and get it working again but can’t do anything if I can’t removing locking ring

any Ideas what I can do there’s not much space between lock ring and frame

View attachment 121281

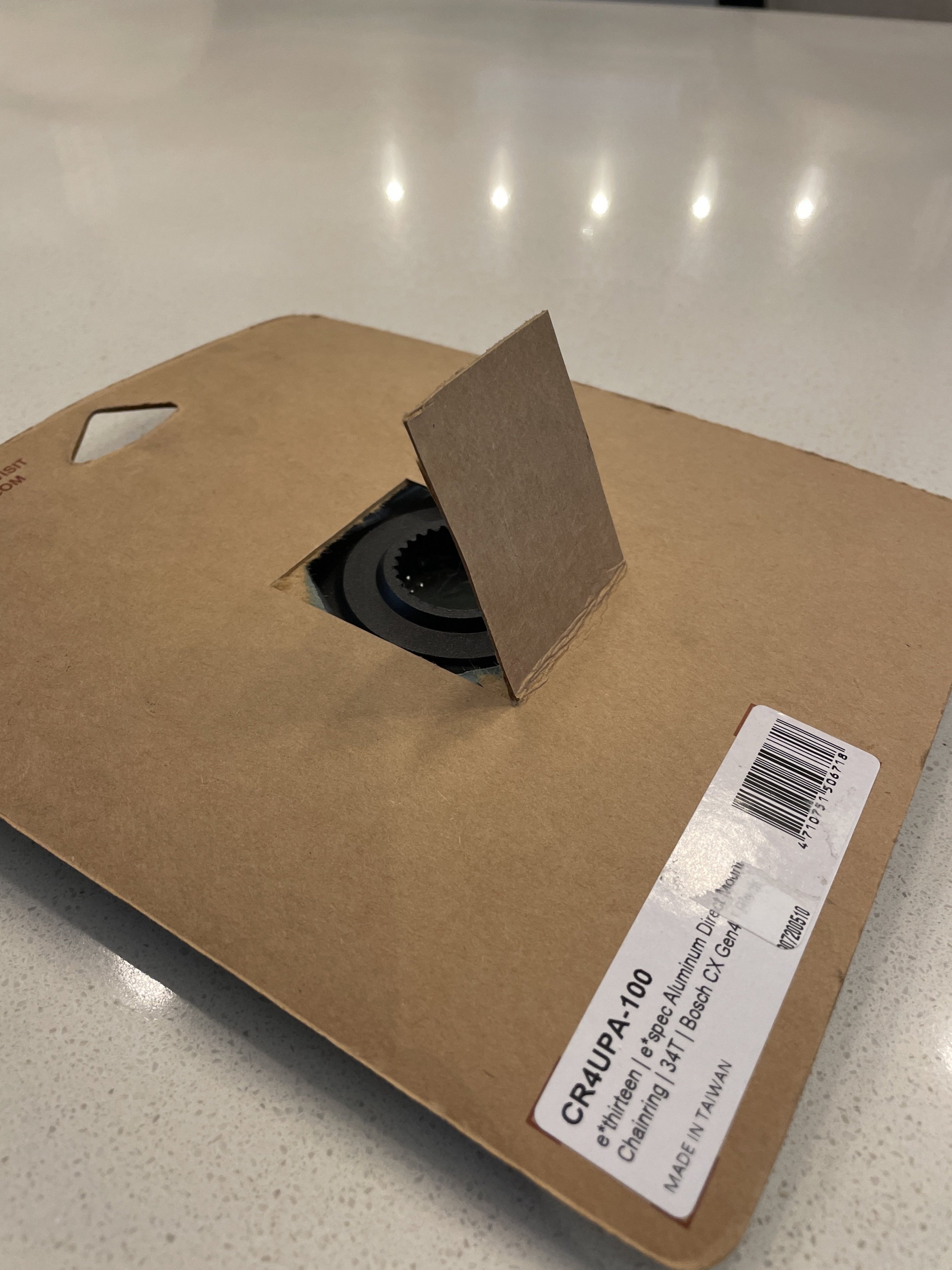

Let me get this right mate, you’re trying to remove the retainer ring to fit a new chainring yeah? if the retainer won’t come off, either cut it extremely carefully, apply some dismantling fluid or take it to your LBS, you could also try to shock it off with a drift and a hammer, just a couple of things to try outAppreciate the reply but there’s nothing to put the chainring on the lock ring is at the end of the threads so nothing to grab onto if u get what I’m saying View attachment 121287

I think that replacing a locking when it becomes loose is an excellent advise.Thought I would add some information for anyone who is upgrading/spec'ing their bike with a SRAM AXS TRANSMISSION Drivetrain. Recently purchased a new Orbea Wild and was having issues with the lockring coming loose on my new bike. I switched out the chainring that came stock on my bike (e13) to the SRAM XX1 EAGLE Transmission chainring. After replacing the lockring twice, decided to take off chainring to measure thickness of SRAM chainring versus the stock e13. The XX1 Transmission chainring is much thicker than the e13 and the bikeshop that installed my the SRAM AXS Transmission Drivetrain left the original aluminum spacer on the Bosch Motor that is need when using the e13 chainring. The Sram chainring comes with the washer "built in" thus being more thicker. After removing the aluminum washer, lockring is fully engaged versus just a couple threads that were holding it on previously. Used a little blue Locktite just in case and have had absolutely no issues with lockring coming loose. Also recommend that if you do need to replace lockring, use a new one. The threads are very fine and seem to distort a little after being tightened.

Thanks!I have said previously when lock rings coming loose has been mentioned that I believe lockrings are single time use only. My reasoning is that a lock ring is secured with very few threads and is a soft ally. Torque of 30nm probably forces some distortion of the thread to achieve maximum thread friction (ie it spreads it a little). The o ring has nothing to do with fit..it is there to protect the motor spigot splines from water/mud etc....ie it is a seal. Similarly any washer is most probably there to achieve a specific chainline.

Finally I believe ally chainrings are probably not a good idea on an emtb due to too much flex. That can also apply to much pressure on the lockring.

So my advice is use a steel chainring and always use a new lockring when changing it.......its only another £10.

That’s a good point.Finally I believe alloy chainrings are probably not a good idea on an emtb due to too much flex. That can also apply to much pressure on the lockring.

Sorry to disagree there Mike but the e13 alloy sprockets are 7050 alloy and 7050 is up there with the best in the business for these applications. For comparison, Renthal 7050 alloy rear sprockets for motocross bikes in the 450cc range put out around 60HP, I would find it highly unlikely that an ebike would put out enough power/torque to flex a 7050 alloy chainring.Finally I believe ally chainrings are probably not a good idea on an emtb due to too much flex.

no comparison in terms of thickness or design ( e.g. distance between the teeth and the central fixing).......put a MX chain up against a 12 speed MTB chain! chalk and cheese! 7075/T6 is very strong in terms of a relationship with its weight in a tube or square section.............here we are talking a bout neither type of construction. Ally is also softer than steel and therefore subject to more wear...............the main reasons for using ally rather than carbon steel is lighter weight and has better anti corrosion, neither of which is much of an advantage in this application in my opinion.Sorry to disagree there Mike but the e13 alloy sprockets are 7050 alloy and 7050 is up there with the best in the business for these applications. For comparison, Renthal 7050 alloy rear sprockets for motocross bikes in the 450cc range put out around 60HP, I would find it highly unlikely that an ebike would put out enough power/torque to flex a 7050 alloy chainring.

That's correct, we're not talking square section or tubing but apples for apples, two sprockets made out of the same material. Get a Renthal 7050 rear sprocket and place an e13 or Raceface mtb sprocet on top. When you compare the shear forces that the Renthal sprocket goes through on a 450 desert racer, it's no more than 2-3 thicker than the mtb sprocket. I'm not buying that the mtb ones flex unless they're not made of 7050.here we are talking a bout neither type of construction

I would find it highly unlikely that an ebike would put out enough power/torque to flex a 7050 alloy chainring.

Same here, I used to run Talon hubs, rims, spokes and sprockets.sprockets from Talon Engineering

The World's largest electric mountain bike community.